Learn with me as I explore what motorcycle dyno tuning does and how it works. I’ll examine how to fine-tune a motorcycle for performance and efficiency and determine what dyno results should look like and how to read them. After successfully dyno-tuning our bikes, we should see smoother rides, faster starts, more power, and better fuel use.

Note: Service your bike before taking it to a dyno centre. Now, let’s start.

In this article:

What is a Motorcycle Dyno?

A motorcycle dyno, or dynamometer, looks like a jogging machine for motorcycles consisting of a rectangular platform with a roller at one end. The tuner places the bike on the dyno platform and securely straps it down with the rear tyre resting on the roller. The motorcycle’s rear wheel spins the roller, and the dyno can measure and calculate your motorcycle’s rear-wheel horsepower, torque, and sometimes speed. There are two types of dyno, inertia and load-bearing dynos:

Inertia Dynos

Intertia dynos are the more straightforward and cheaper of the two dynamometers. They rely on a heavy roller with a known weight (mass). The dyno measures how quickly the bike accelerates the roller. Using the acceleration data, the dyno can calculate horsepower and torque. Inertia dynos can simulate wide-open throttle runs (WOT). Let’s look at the advantages and disadvantages of inertia dynos.

Advantages of an inertia dyno:

- Simpler and typically less expensive.

- Good for baseline power measurements and straightforward tuning tasks.

- Requires less expertise to operate.

Disadvantages of an inertia dyno:

- Cannot simulate real-world riding conditions like varying loads (e.g., uphill climbs or strong headwinds).

- Less effective for part-throttle tuning or simulating dynamic conditions.

Load-Bearing Dynos

The other primary dyno type is a load-bearing dyno that can apply a variable resistance (load) to the roller via an electromagnetic brake or hydraulic system. This resistance can simulate real-world conditions such as inclines, wind resistance, or heavy loads. These dynos can measure power output while holding the motorcycle at specific speeds, RPMs, or throttle positions. Let’s look at load-bearing dynos’ advantages and disadvantages.

Advantages of a load-bearing dyno:

- It simulates real-world conditions more accurately, such as hills, wind, passenger loads, gear ratios, etc., making it better suited for advanced tuning and diagnostics.

- Excellent for tuning at part throttle or under specific loads, which is critical for street bikes and fuel efficiency optimization.

- Useful for steady-state tuning and emissions testing.

Disadvantages of a load-bearing dyno:

- More complex and expensive.

- Requires more expertise to operate and tune effectively.

- Testing takes longer compared to inertia dynos.

Connecting Sensors and Diagnostics

Technicians and tuning specialists connect diagnostic equipment to the motorcycle to better understand its performance. They attach sensors to monitor engine RPM, air-fuel ratio, throttle position, and manifold pressure (if applicable). The dyno itself measures rear-wheel horsepower, torque, and sometimes speed. The tuner in the following video connects the RPM pickup wire to a spark plug wire, allowing him to test for RPM, horsepower, and speed.

![]()

Ways to Connect to the Motorcycle

Depending on the dyno and tuner, here are some common ways sensors are attached to the motorcycle.

RPM Sensor / Measurement: A sensor (like an optical or inductive pickup) is attached to the motorcycle’s ignition system to monitor engine RPM. This can be done by connecting to a spark plug wire or a crankshaft position sensor. The data helps correlate the roller’s speed with engine performance. See the above video.

Air-Fuel Ratio (AFR) Sensor / Measurement: An oxygen sensor (O2 sensor) is inserted into the exhaust to measure the air-fuel mixture. This data is necessary for tuning fuel delivery and ensuring proper combustion.

Throttle Position Sensor (TPS): Sometimes, the dyno connects to the bike’s throttle position sensor (via diagnostic ports or piggyback systems) to monitor throttle input during testing.

Manifold Pressure or Boost Sensor: A boost gauge or pressure sensor may be used to monitor intake pressure on forced-induction bikes.

Testing the Bike’s Performance

Now, let’s focus on testing the bike to see how it performs before any tuning. We have to do what is called a baseline run. The following video clip introduces an initial baseline run with Lamb Chop Rides’ ![]() Suzuki GSX-S1000 GX on a dyno at Steve Jordan Motorcycles

Suzuki GSX-S1000 GX on a dyno at Steve Jordan Motorcycles ![]() in the UK.

in the UK.

Baseline Run

A baseline run records the motorcycle’s current performance levels before any tuning, just as the bike was when you rode it (or delivered it) to the tuning place. The engine is run through various RPM ranges and throttle positions to map its current power and torque output. This baseline data helps identify areas needing attention. As its name suggests, the tuner can have a baseline to measure tuning improvements.

Engine Adjustments

After the baseline run, depending on the result data, the technician can adjust the bike to improve its performance. They might change the air-fuel ratio (AFR) to ensure an optimal mix of fuel and air for combustion, and they can adjust the ignition timing to set when the spark plug fires. They will focus on throttle response and fine-tune how quickly the engine reacts to throttle inputs. The technician can connect to the ECU to fine-tune the bike even more.

After each adjustment to the motorcycle, the dyno tech performs another dyno run to assess the impact of the changes. They repeat this process until they achieve the desired performance levels, including power, torque and smoothness.

Finalising and Road Test

Once tuning is complete, they test the motorcycle across its entire RPM and throttle range to ensure consistent performance. Finally, it’s time to take the bike onto the road for a real-world test to check that the tuning has worked. The tuner generates a final dyno chart showing improved horsepower and torque curves for the rider to keep.

How to read a Dyno Chart

A dyno chart represents a motorcycle’s performance, showing its horsepower and torque output across different engine speeds (RPM).

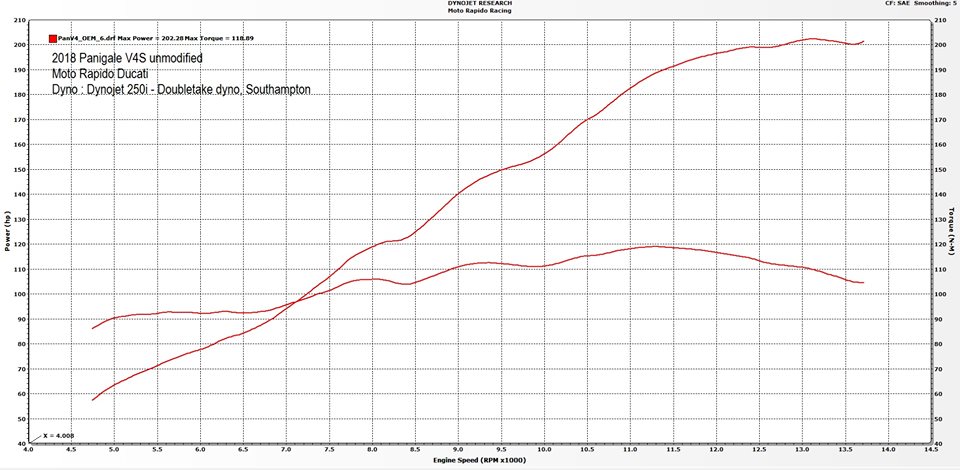

Typically, a dyno chart consists of a horizontal (X-axis) along the bottom representing engine speed in RPM (Revolutions Per Minute). As you go right on the graph, the RPM increases. The vertical (Left Y-axis) typically shows horsepower (hp), measuring the engine’s power output. Higher on the graph means more horsepower. The vertical (Right Y-axis) typically shows torque (lb-ft or Nm), a measure of the engine’s twisting or pulling force. Higher on the graph means more torque. During a dyno test, curves representing horsepower and torque are drawn on the chart. Let’s study the performance characteristics from the example dyno chart above.

Power (202 hp)

The dyno graph spans from 4,000 to 14,000 RPM. The steeper horsepower curve shows how the engine’s power output changes as the RPM increases. A horsepower curve typically climbs more steeply as RPM increases and shows the engine’s peak power output. In the above example, the max power output is approximately 202 hp (horsepower). This is achieved near the upper RPM range, around 13,000-14,000 RPM.

Torque (119 Nm)

The lower torque curve shows the engine’s rotational force at various RPMs and is usually a flatter, more consistent curve. Torque often peaks at a lower RPM than horsepower. A torque curve shows how much “pulling power“ the engine has. In the example above, the max torque is approximately 119 Nm (Newton-meters). This peak occurs earlier in the RPM range (than the max power output) at around 11,000 RPM.

Power Curve:

- The power increases steadily as RPM rises, peaking near the rev limiter.

- Smooth and consistent power delivery, indicative of a well-tuned engine with no sudden dips or irregularities.

Torque Curve:

- Torque builds strongly from mid-RPM (around 6,000 RPM) and peaks around 11,000 RPM.

- After the peak, torque begins to taper off, but power continues to climb as RPM increases.

Power vs. Torque:

- The smooth transition between torque and power delivery ensures optimal performance throughout the RPM range.

- The engine delivers strong mid-range torque for acceleration and high peak power for top-end performance.

Look for the Peaks

The peaks in the curves represent the maximum power reached at a particular engine RPM. Peak power is the highest point on the horsepower curve, telling you the engine’s maximum power at a specific RPM. This is a primary focus for high-speed performance.

Peak torque is the highest point on the torque curve which tells you the maximum twisting force the engine produces at that RPM and helps assess how much pulling power the bike has and at what RPM it’s available. Peak torque is desirable for low and mid-range performance. Any dips you see in a dyno graph are usually from changing gears.

Analyze the Curves

A steep horsepower curve indicates an engine that produces most of its power at higher RPMs. A flat torque curve shows an engine with good power delivery available across a wide RPM range, making the engine feel responsive in many gears or speeds. By analysing the curves and other performance data, the dyno tuner can see the differences before and after tweaking or modifying the bike or adding performance parts like custom exhausts.

Connecting to the ECU (Electronic Control Unit) (Optional)

Modern motorcycles have sophisticated ECUs (Electronic Control Units) that manage the engine’s performance. In some cases and for more advanced tuning or customisation, the dyno operator may connect to the motorcycle’s diagnostic port to access additional data from the ECU, such as engine load, ignition timing, or sensor readings like intake air temperature and coolant temperature.

A professional motorcycle tuner can also turn on and off features within the ECU that some riders don’t need or want. For example, for Euro 5 motorcycle regulations, some bikes have features to limit exhaust emissions. If some riders use the bike only on the track instead of the road, they could theoretically turn these options off via the ECU.

Flashing: The technician can also flash a new set of instructions to the ECU to replace those from the factory. It’s good to point out that each motorcycle is different. Just because it’s the same make and model bike doesn’t mean you can flash an ECU and expect the same tuning results as someone else’s bike.

Connecting to the ECU is not required for basic dyno runs but can be helpful for detailed tuning. Separate tuning tools, software, or aftermarket controllers are used to communicate and adjust ECU settings.

ECU access: Allows tuning specialists to read and adjust various parameters like:

- Fuel mapping

- Ignition timing

- Throttle response

- Other engine parameters

How to connect to the ECU: There are a few different ways to connect to the ECU:

- Diagnostic port: Many bikes have a diagnostic port to connect to the ECU.

- Direct connection: In some cases, the tuner might need to connect directly to the ECU’s wiring harness.

- ECU flashing: Some tuners might even reflash the ECU with a new map to optimize performance.

Important Note: The exact method of connecting to the ECU and the level of access will depend on the specific motorcycle model and the type of dyno being used.

Key points to remember about ECU tuning

- The dyno itself doesn’t connect directly to the ECU but relies on external sensors and the bike’s mechanical output.

- Any ECU adjustments during dyno tuning are made via separate tuning tools or software that interface with the motorcycle’s ECU or an aftermarket controller.

Another Dyno run example

Check out this video clip showing a dyno chart in real-time during a 2019 Yamaha Niken GT dyno test. (Chart starts at 48 secs)

FAQ

What is motorcycle dyno tuning?

Motorcycle dyno tuning is a way to measure a motorcycle’s power. It uses a dynamometer to measure engine performance and form a baseline for adjustments and improvements.

How long does a typical dyno tuning session take?

A dyno-tuning session can take several hours. Fine-tuning a bike takes time and requires multiple dyno runs. This ensures the bike performs well at different speeds and throttle positions.

What are the Benefits of Dyno Tuning?

Dyno tuning can help you get the most out of your motorcycle’s engine. You can feel and enjoy performance gains with the increased horsepower and torque. A properly tuned engine will run more efficiently, saving you money on fuel. A well-tuned engine will produce fewer emissions, which is better for the environment. Dynoing helps identify engine problems that may affect performance or the engine’s health. Dyno tuning allows you to customise the ride and feel of the bike to your specific needs.

How should I prepare my motorcycle for dyno tuning?

Service your bike before visiting a dyno tuner.

How important is ignition timing in dyno tuning?

Ignition timing is key in dyno tuning. It affects the engine’s performance. Correct timing prevents engine damage and boosts power.

What are some common mistakes to avoid during dyno tuning?

Avoid tuning on a bike that’s not well-maintained. Don’t ignore part-throttle performance. Focus on real-world riding conditions, not just peak power.

Is dyno tuning a one-time process?

Dyno tuning is often ongoing. The engine may need adjustments over time. Regular checks and retuning are wise after changes or wear.